INFORMATION QUOTED FROM DEKRA 2011

AUTOMOTIVE LUBRICANTS

Additive

Additive

Additives are mixed with base stocks in order to Impart properties to the finished oil which are required for service, but are not as such inherent in the base oil. Maintain function of the finished product over a long time even under conditions of maximum operational stress

Friction Modifier

Friction Modifier

Problem: synchronized manual transmissions, automatic transmissions and wet brakes in tractors require certain friction coefficients.

Solution: additives provide the required frictional characteristics to metal surfaces.

1. Anti-Foam Additives

Problem: intensive mixing of oil with air during operation results in foaming which increases oil oxidation and viscosity. Oil foam is compressible, interfering with hydraulic tappet operation.

Solution: additives prevent/reduce foaming.

2. Metal Deactivators

Problem: microscopic metallic debris in the oil accelerates oil oxidation catalytically.

Solution: additives deactivate the catalytic effect and from protective layers on metal surfaces.

3. Anti-Oxidants

Problem: high temperatures and oxygen lead to oxidation of the oil which darkens, becomes acid and increases in viscosity.

Solution: additives prevent or reduce oxidative attack and the formation of oxidation products.

Improving the oil

Improving the oil

1. Seal Swell Agents

Problem: certain synthetic hydrocarbons (e.g. PAO) can lead to shrinking》drying out《 of elastomer materials (e.g. radial shaft seals).

Solution: additives prevent the drying out of elastomers, the component remains tight.

2. Pour Point Depressants

Problem: mineral oils precipitate paraffinic wax crystals at low temperatures which congeal, causing the oil to become solid.

Solution: additives prevent the coagulation of wax crystals, the oil remains fluid even at low cold start temperatures.

3. Viscosity Modifiers

Problem: easy cold start at low temperatures (oil must not be too viscous), safe lubrication at high temperatures (oil must not be too thin).

Solution: additives turn a low viscosity (cold-start safe) monograde oil (e.g. SAE 10 W) into a more viscous wide-range multigrade oil by thickening effects at high temperatures (e.g. SAE 10W-40)

Volatility of the oil needs to be observed!

Special Additives

Special Additives

Optimum efficiency of additives is only possible if all additives in the formulation are present in the right concentration. Any subsequent addition disturbs the balance between components and can have a disadvantageous effect on the performance. This is why all vehicle manufacturers reject the unauthorized addition of "special additives"to fully formulated oils.

Viscosity

Viscosity

Is the resistance of a fluid against flow. The viscosity changes with temperature:

Cold oil is relatively viscous (like honey)

Cold oil is relatively viscous (like honey)

Hot oil is relatively thin (like diesel fuel/heating oil)

Hot oil is relatively thin (like diesel fuel/heating oil)

SAE Viscosity Classification

SAE Viscosity Classification

(SAE= Society of Automotive Engineers) for engine oils and for automotive transmissions are recognized worldwide, see table.

SAE Grades are not performance requirements!

Viscosity Index

Viscosity Index

The viscosity change due to changes of temperature can differ from one oil to another; this is described by the Viscosity Index (;VI;), a nondimensional quantity. Single grade oils have a VI about 100 whereas multigrade oils have a VI of up to 150, depending on their viscosity range.

Viscosity: Measurements and Dimensions

Viscosity: Measurements and Dimensions

Three types of viscometer are in common use

Capillary viscometers

Capillary viscometers

Rotational viscometers

Rotational viscometers

Falling ball viscometers (only for used oil).

Depending on the viscometer type the following viscosities are measured

Falling ball viscometers (only for used oil).

Depending on the viscometer type the following viscosities are measured

Kinematic viscosity: mm2/s, formerly cSt (centi Stokes),

Kinematic viscosity: mm2/s, formerly cSt (centi Stokes),

Dynamic viscosity: mPa.s (milli Pascal seconds), formerly Cp (centi Poise).

Dynamic viscosity: mPa.s (milli Pascal seconds), formerly Cp (centi Poise).

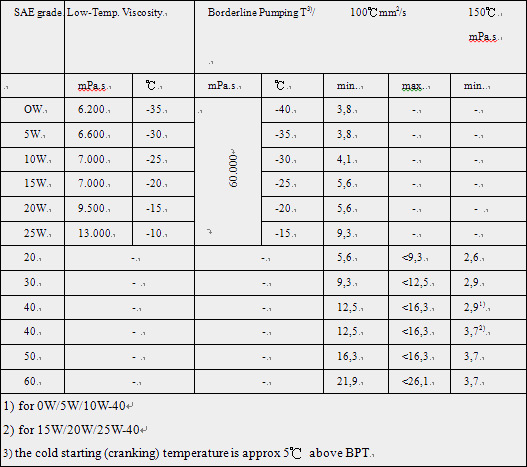

Engine Oils: Low temperature operation

Engine Oils: Low temperature operation

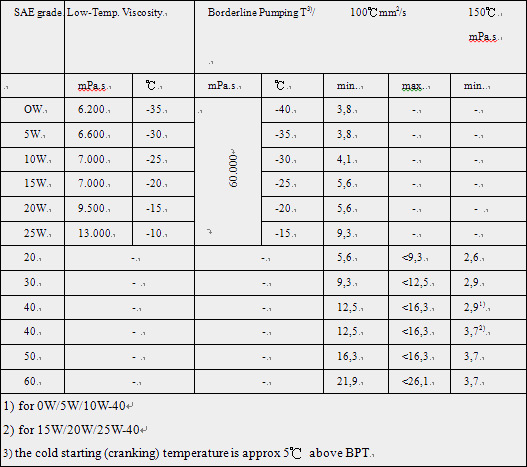

The starter motor must be able to turn over the cold engine with the required minimum cranking speed and oil must be delivered to all lubricating points as quickly as possible (rocker arm oiling time!). Details: table Engine Oils Viscosity Grades.

Engine Oils: Borderline Pumping Temperature(BPT)

Engine Oils: Borderline Pumping Temperature(BPT)

The BPT is the lowest temperature at which the oil still flows to the pump inlet on its own. Below the BPT the pump may deliver air instead of oil, causing oil starvation and engine damage. A lot BPT is therefore most important to ensure adequate engine lubrication at low cold start temperatures. Details: table Engine Oils Viscosity Grades.

Engine Oils: High temperature operation

Engine Oils: High temperature operation

All lubricated components must have a continuous oil film of sufficient load carrying capacity at all times; the temperature at the top of the piston (top land) can be as high as 300℃. This is the temperature which determines the selection of the correct viscosity level, not the ambient temperature.

Engine Oils: High Temperature Viscosity (HTHS)

Engine Oils: High Temperature Viscosity (HTHS)

SAE, ACEA and several vehicle manufacturers specify a minimum viscosity for engine oils at an oil temperature of 150℃ and at high shear rate (high engine speed). This is the HTHS-viscosity (High Temperature High Shear) which correlates better with practical operating conditions than the viscosity at 100℃.

Engine Oils: SAE grades (see table)

Engine Oils: SAE grades (see table)

SAE 0W, 5W, 10W,15W,20W,25W→cold start

SAE 0W, 5W, 10W,15W,20W,25W→cold start

SAE 20,30,40,50,60→high temperature operation

SAE 20,30,40,50,60→high temperature operation

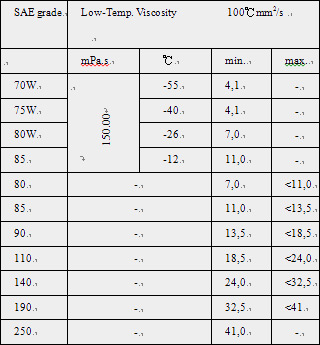

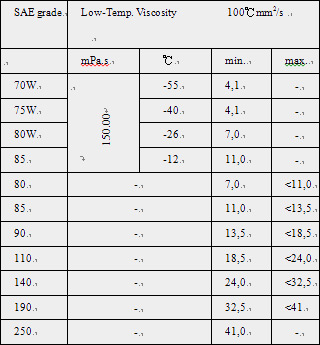

Gear Oils: SAE-Klassen (see table)

SAE 70W,75W,80W,85W→cold start

SAE 70W,75W,80W,85W→cold start

SAE 80,85,90,110,140,190,250→high temperature operation

SAE 80,85,90,110,140,190,250→high temperature operation

Engine Oils Viscosity Grades- SAE J300

Gear Oils Viscosity Grades-SAE J306

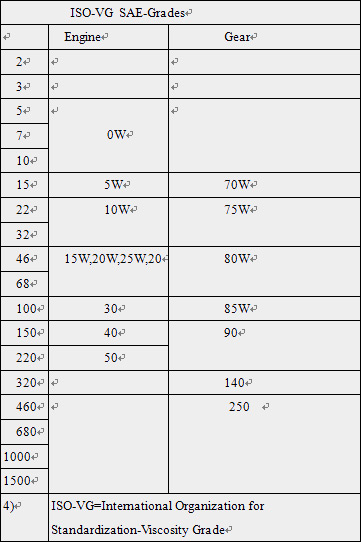

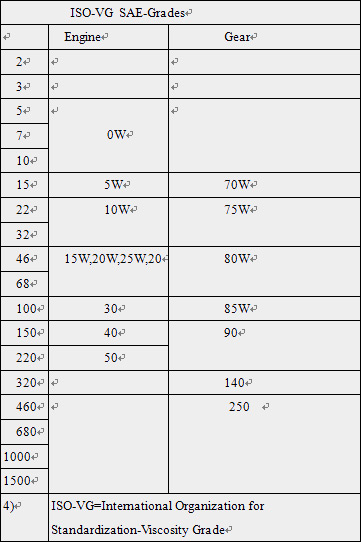

ISO Viscosity Classification for Industrial Liquid

Lubricants- ISO-VG4

This is applicable to all lubricants with the exception of automotive engine oils or transmission lubricants.

There are 18 different viscosity grades,

from 2 mm2/s (like diesel fuel)

from 2 mm2/s (like diesel fuel)

up to1500 mm2/s (cylinder oil)

up to1500 mm2/s (cylinder oil)

The reference temperature is always 40℃

ISO-VG/SAE Comparison (approximate equivalents)

Base Oils-Additives-Viscosity

Base Oils

Base Oils

Automotive lubricants consist of base oil(s) and additives. All base oils, refined petroleum fractions, hydrocracked stocks, synthetic hydrocarbons(PAO,PIB,PIO) and Synthetic base stocks(e.g. ester) are derived from crude oil. Vegetable oils such as rape seed oil are used on a very small scale, for example as hydraulic oil.

Performance of Raffinates

Performance of Raffinates

Refined products have normal oxidation stability (normal oil drain intervals) and can be produced at relatively low cost. The lower their viscosity, the higher is their volatility at high temperatures. Their low temperature performance (pour point) is moderate and usually needs to be improved by the use of additives. The Viscosity Index (VI) is approx. 90 to 100, typical for single grade oils. To produce a multigrade oil from such a raffinate it is necessary to add viscosity modifiers (earlier called " VI-improvers") volatility needs to be observed!

1. Synthesis

Combining very small HC molecules (gases ethane C2H4 or propene C3H6) to form lubricating oil molecules. Rommps Chemical Dictionary defines as follows (extract): "Synthesis: term describing the artificial production of chemical compounds from their elements, stepwise from simple compounds or by reaction between compounds of equal magnitude.

2. Hydrofinishing

Final treatment with hydrogen to achieve optimum oxidation stability and removal of sulphur.

3. Catalytic Hydrocracking

Hydrocrack process in the presence of a catalyst to attain specific process conditions.

4. Hydrocracking

Breaking up of HC molecules larger then C35 down to oil molecule size in the presence of hydrogen which adjoins and "repairs" the fracture sites..

4. Hydrocracking

Breaking up of HC molecules larger then C35 down to oil molecule size in the presence of hydrogen which adjoins and "repairs" the fracture sites..

5. Cracking

Breaking up gasoline HC molecules C5 to C12 down to gas molecules C2 ethene and C3 propene as feedstock for the production of synthetic hydrocarbons (PAO, PIB, PIO).

6. Dewaxing

Removing normal paraffins with poor low temperature properties by adding solvents, refrigerating and filtering out paraffinic wax. Improvement of pour point and low temperature performance.

7. Refining

Removing/reforming undesirable or harmful (unstable) components from vacuum distillate fractions. This improves oxidation stability, viscosity/temperature relationship (higher VI= multigrade characteristics) and cold start performance (lowering of pour point).

8. Vacuum Distillation

Separation of atmospheric distillation residue under vacuum, whereby distillation temperature is reduced by approx. 150℃ in order to avoid cracking. Lube oil fractions of different viscosity levels are produced, the rest is vacuum residue.

9. Distillation

Separation of crude oil fractions by heating, evaporating and condensing at atmospheric pressure to produce gasoline and diesel fuel/heating oil (middle distillate). The remainder is atmospheric residue

Performance of Hydrocrack Oils and Synthetic Hydrocarbons

Performance of Hydrocrack Oils and Synthetic Hydrocarbons

Special advantage of this type of base stock compared to conventional raffinates is their more uniform composition. This provides them with much better oxidation stability (required for extended oil change intervals) and with lower evaporative losses (oil-related oil consumption). Their Viscosity Index (VI) is about 130 to 150, typical for multi-grade oils. The pour point (low temperature behaviour) of PAO is below -40℃, that of hydrocrack oils is below -35℃.

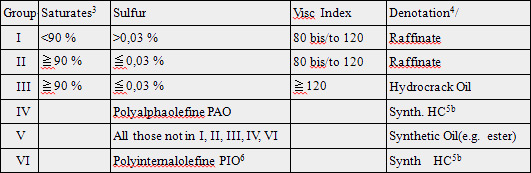

Base Oils: Product Descriptions

Base Oils: Product Descriptions

Raffinates, hydrocrack oils, synthetic hydrocarbons and certain esters are employed alone or in different mixtures to provide base stocks. None of these descriptions (raffinate, hydrocrack oil, synthetic hydrocarbons, synthetic oils) or any of the other word combinations are standardized or even suitable for standardization. The sales literature of oil marketers includes the following word creations: Synthetic, fully synthetic, part-synthetic, parasynthetic, semisynthetic, polysynthetic, with synthetic components, synthetic based, synthetic technology, hydrocraked, moleculary converted, HC-synthesis. These descriptions do not provide precise information on the real composition of the oils. They are only marketing terms.

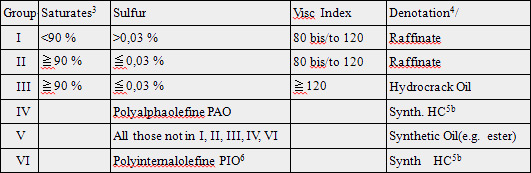

1. API=American Petroleum Institute

2. ATIEL=Association Technique de I'Industrie Europeenne des Lubrifiants

3. Contents of saturated HC-compounds, important for oxidation stability(oil change intervals!)

4. Common descriptions, not mentioned by API and ATIEL

5. Synthetic hydrocarbons

6. new development, for ATIEL only

Base Oils: International Classification

Base Oils: International Classification

There are no national or international standard definitions of base oils. When formulating lubricating oils the base oil groups according go API1) and ATIEL 2) are in worldwide use.

Other Base Stocks: Recycled Base Oils

Other Base Stocks: Recycled Base Oils

Directive 87 / 101 / EWG requires that re-refining of used oils is given preference to incineration

Used oil as feedstock

Sedimentation / filtration

Sedimentation / filtration

Distillation

Distillation

Vacuum distillation

Vacuum distillation

Refining

Refining

The performance of re-refined base stocks is similar to that of virgin stocks.

Other Base Stocks: Synthetic Oils

Other Base Stocks: Synthetic Oils

Basic building blocks are hydrocarbons, additional constituents may be:

Oxygen (O) e.g. synthetic esters, polyglycols

Oxygen (O) e.g. synthetic esters, polyglycols

Phosphorus (P + O) e.g. phosphate esters

Phosphorus (P + O) e.g. phosphate esters

Silicon (Si + O) e.g. silicones

Silicon (Si + O) e.g. silicones

Synthetic esters are sometimes used to formulate rapidly biodegradeable hydraulic oils and motor oils.

AUTOMOTIVE LUBRICANTS

Additives are mixed with base stocks in order to Impart properties to the finished oil which are required for service, but are not as such inherent in the base oil. Maintain function of the finished product over a long time even under conditions of maximum operational stress

Problem: synchronized manual transmissions, automatic transmissions and wet brakes in tractors require certain friction coefficients.

Solution: additives provide the required frictional characteristics to metal surfaces.

1. Anti-Foam Additives

Problem: intensive mixing of oil with air during operation results in foaming which increases oil oxidation and viscosity. Oil foam is compressible, interfering with hydraulic tappet operation.

Solution: additives prevent/reduce foaming.

2. Metal Deactivators

Problem: microscopic metallic debris in the oil accelerates oil oxidation catalytically.

Solution: additives deactivate the catalytic effect and from protective layers on metal surfaces.

3. Anti-Oxidants

Problem: high temperatures and oxygen lead to oxidation of the oil which darkens, becomes acid and increases in viscosity.

Solution: additives prevent or reduce oxidative attack and the formation of oxidation products.

1. Seal Swell Agents

Problem: certain synthetic hydrocarbons (e.g. PAO) can lead to shrinking》drying out《 of elastomer materials (e.g. radial shaft seals).

Solution: additives prevent the drying out of elastomers, the component remains tight.

2. Pour Point Depressants

Problem: mineral oils precipitate paraffinic wax crystals at low temperatures which congeal, causing the oil to become solid.

Solution: additives prevent the coagulation of wax crystals, the oil remains fluid even at low cold start temperatures.

3. Viscosity Modifiers

Problem: easy cold start at low temperatures (oil must not be too viscous), safe lubrication at high temperatures (oil must not be too thin).

Solution: additives turn a low viscosity (cold-start safe) monograde oil (e.g. SAE 10 W) into a more viscous wide-range multigrade oil by thickening effects at high temperatures (e.g. SAE 10W-40)

Volatility of the oil needs to be observed!

Optimum efficiency of additives is only possible if all additives in the formulation are present in the right concentration. Any subsequent addition disturbs the balance between components and can have a disadvantageous effect on the performance. This is why all vehicle manufacturers reject the unauthorized addition of "special additives"to fully formulated oils.

Is the resistance of a fluid against flow. The viscosity changes with temperature:

(SAE= Society of Automotive Engineers) for engine oils and for automotive transmissions are recognized worldwide, see table.

SAE Grades are not performance requirements!

The viscosity change due to changes of temperature can differ from one oil to another; this is described by the Viscosity Index (;VI;), a nondimensional quantity. Single grade oils have a VI about 100 whereas multigrade oils have a VI of up to 150, depending on their viscosity range.

Three types of viscometer are in common use

The starter motor must be able to turn over the cold engine with the required minimum cranking speed and oil must be delivered to all lubricating points as quickly as possible (rocker arm oiling time!). Details: table Engine Oils Viscosity Grades.

The BPT is the lowest temperature at which the oil still flows to the pump inlet on its own. Below the BPT the pump may deliver air instead of oil, causing oil starvation and engine damage. A lot BPT is therefore most important to ensure adequate engine lubrication at low cold start temperatures. Details: table Engine Oils Viscosity Grades.

All lubricated components must have a continuous oil film of sufficient load carrying capacity at all times; the temperature at the top of the piston (top land) can be as high as 300℃. This is the temperature which determines the selection of the correct viscosity level, not the ambient temperature.

SAE, ACEA and several vehicle manufacturers specify a minimum viscosity for engine oils at an oil temperature of 150℃ and at high shear rate (high engine speed). This is the HTHS-viscosity (High Temperature High Shear) which correlates better with practical operating conditions than the viscosity at 100℃.

Gear Oils: SAE-Klassen (see table)

Engine Oils Viscosity Grades- SAE J300

Gear Oils Viscosity Grades-SAE J306

ISO Viscosity Classification for Industrial Liquid

Lubricants- ISO-VG4

This is applicable to all lubricants with the exception of automotive engine oils or transmission lubricants.

There are 18 different viscosity grades,

The reference temperature is always 40℃

ISO-VG/SAE Comparison (approximate equivalents)

Base Oils-Additives-Viscosity

Automotive lubricants consist of base oil(s) and additives. All base oils, refined petroleum fractions, hydrocracked stocks, synthetic hydrocarbons(PAO,PIB,PIO) and Synthetic base stocks(e.g. ester) are derived from crude oil. Vegetable oils such as rape seed oil are used on a very small scale, for example as hydraulic oil.

Refined products have normal oxidation stability (normal oil drain intervals) and can be produced at relatively low cost. The lower their viscosity, the higher is their volatility at high temperatures. Their low temperature performance (pour point) is moderate and usually needs to be improved by the use of additives. The Viscosity Index (VI) is approx. 90 to 100, typical for single grade oils. To produce a multigrade oil from such a raffinate it is necessary to add viscosity modifiers (earlier called " VI-improvers") volatility needs to be observed!

1. Synthesis

Combining very small HC molecules (gases ethane C2H4 or propene C3H6) to form lubricating oil molecules. Rommps Chemical Dictionary defines as follows (extract): "Synthesis: term describing the artificial production of chemical compounds from their elements, stepwise from simple compounds or by reaction between compounds of equal magnitude.

2. Hydrofinishing

Final treatment with hydrogen to achieve optimum oxidation stability and removal of sulphur.

3. Catalytic Hydrocracking

Hydrocrack process in the presence of a catalyst to attain specific process conditions.

4. Hydrocracking

Breaking up of HC molecules larger then C35 down to oil molecule size in the presence of hydrogen which adjoins and "repairs" the fracture sites..

4. Hydrocracking

Breaking up of HC molecules larger then C35 down to oil molecule size in the presence of hydrogen which adjoins and "repairs" the fracture sites..

5. Cracking

Breaking up gasoline HC molecules C5 to C12 down to gas molecules C2 ethene and C3 propene as feedstock for the production of synthetic hydrocarbons (PAO, PIB, PIO).

6. Dewaxing

Removing normal paraffins with poor low temperature properties by adding solvents, refrigerating and filtering out paraffinic wax. Improvement of pour point and low temperature performance.

7. Refining

Removing/reforming undesirable or harmful (unstable) components from vacuum distillate fractions. This improves oxidation stability, viscosity/temperature relationship (higher VI= multigrade characteristics) and cold start performance (lowering of pour point).

8. Vacuum Distillation

Separation of atmospheric distillation residue under vacuum, whereby distillation temperature is reduced by approx. 150℃ in order to avoid cracking. Lube oil fractions of different viscosity levels are produced, the rest is vacuum residue.

9. Distillation

Separation of crude oil fractions by heating, evaporating and condensing at atmospheric pressure to produce gasoline and diesel fuel/heating oil (middle distillate). The remainder is atmospheric residue

Special advantage of this type of base stock compared to conventional raffinates is their more uniform composition. This provides them with much better oxidation stability (required for extended oil change intervals) and with lower evaporative losses (oil-related oil consumption). Their Viscosity Index (VI) is about 130 to 150, typical for multi-grade oils. The pour point (low temperature behaviour) of PAO is below -40℃, that of hydrocrack oils is below -35℃.

Raffinates, hydrocrack oils, synthetic hydrocarbons and certain esters are employed alone or in different mixtures to provide base stocks. None of these descriptions (raffinate, hydrocrack oil, synthetic hydrocarbons, synthetic oils) or any of the other word combinations are standardized or even suitable for standardization. The sales literature of oil marketers includes the following word creations: Synthetic, fully synthetic, part-synthetic, parasynthetic, semisynthetic, polysynthetic, with synthetic components, synthetic based, synthetic technology, hydrocraked, moleculary converted, HC-synthesis. These descriptions do not provide precise information on the real composition of the oils. They are only marketing terms.

1. API=American Petroleum Institute

2. ATIEL=Association Technique de I'Industrie Europeenne des Lubrifiants

3. Contents of saturated HC-compounds, important for oxidation stability(oil change intervals!)

4. Common descriptions, not mentioned by API and ATIEL

5. Synthetic hydrocarbons

6. new development, for ATIEL only

There are no national or international standard definitions of base oils. When formulating lubricating oils the base oil groups according go API1) and ATIEL 2) are in worldwide use.

Directive 87 / 101 / EWG requires that re-refining of used oils is given preference to incineration

Used oil as feedstock

The performance of re-refined base stocks is similar to that of virgin stocks.

Basic building blocks are hydrocarbons, additional constituents may be:

Synthetic esters are sometimes used to formulate rapidly biodegradeable hydraulic oils and motor oils.